Managed Inventory Programs

QUAL-FAB ensures consistent on-time product delivery with our specialized (ERP) software system. We recognize the importance of managing customer inventory levels to reduce carrying costs and space requirements.

We continually review usage-and-forecast reports in light of current inventories to ensure maximum inventory levels are maintained. QUAL-FAB has had great success in working with customers to develop and implement the following programs:

Sheet metal fabrication capabilities from prototype through production

Sheet Metal Fabrication

QUAL-FAB offers punching, laser cutting, precision brake forming, and welding sheet metal fabrication services. With the latest technology, we have massive capacity, guaranteed quality, and great prices.

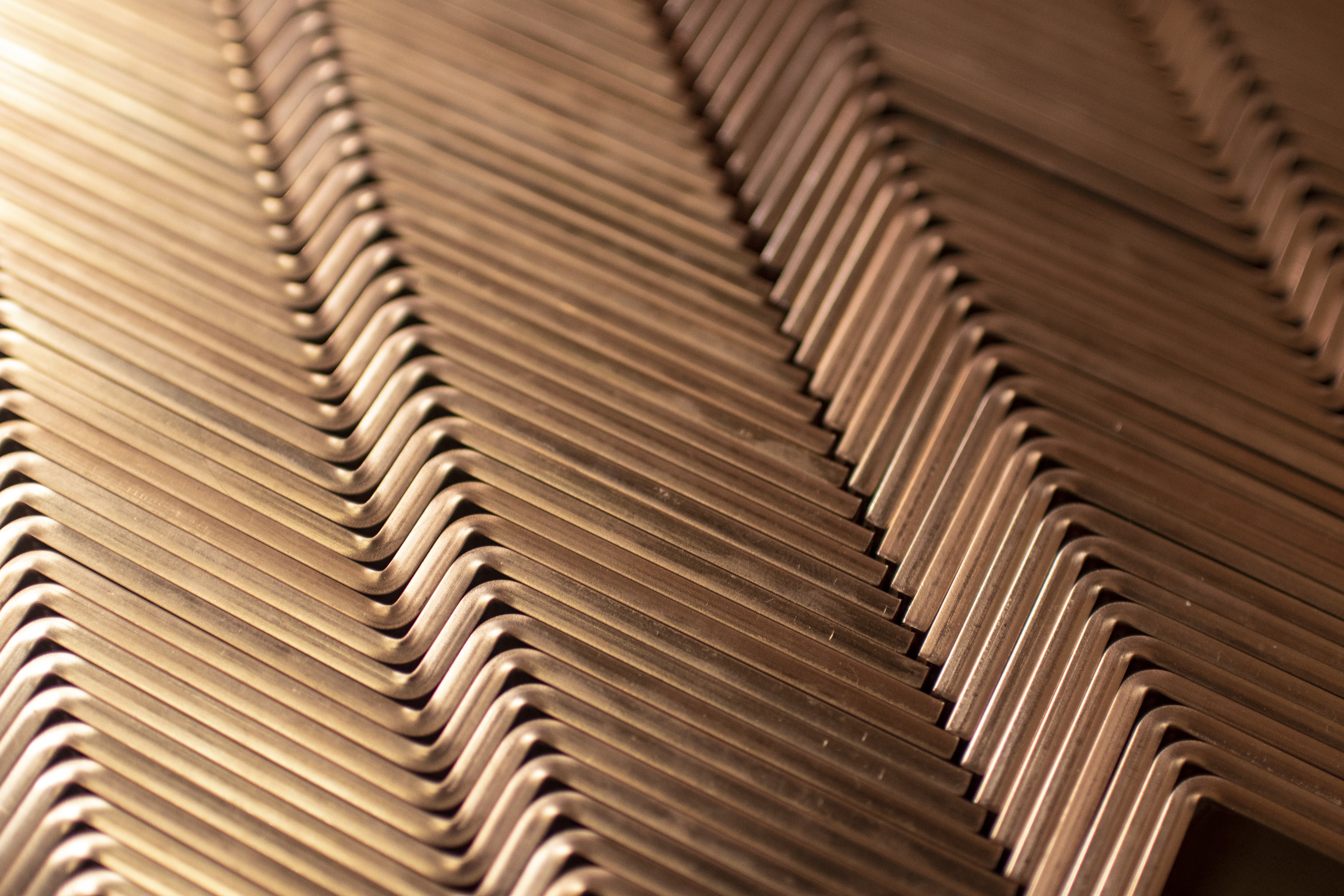

Precision Brake Forming

Precision brake forming is used to form and bend sheet metal into U-shaped, V-shaped, and channel-shaped parts. This process demands expertise and knowledge of the metal to fabricate a part that performs as required in the finished product.

Mechanical Assembly

QUAL-FAB has a designated facility for staging, assembly, final inspection, and finished goods distribution.

Punching

In addition to forming tooling such as louvers, embosses, lance forms, knock-outs, and countersinks, we also offer a large assortment of standard and special shape tooling.

Welding

We offer MIG Welding and TIG Welding for simple to complex weldments. We use a calibrated tensile tester for process control. QUAL-FAB also offers spot welding for both steel and aluminum parts.

Managed Inventory Programs

QUAL-FAB ensures consistent on-time product delivery with our specialized (ERP) software system. We recognize the importance of managing customer inventory levels and utilize customized inventory solutions to reduce carrying costs and space requirements.

Laser Cutting

Laser cutting one of the most flexible and consistent methods to cut sheet metal. QUAL-FAB invests in a top-of-the-line 2,000 Watt CNC Laser to ensure clean lines and a smooth finish.

Hardware Insertion & Fastening

We use Haeger Insertion machines to install fasteners such as PEM hardware, POP rivets, Riv-nuts, Spin-tite nuts, and Weld nuts.

Engineering & Design Assistance

We offer a complete prototype-through-production analysis of your product and assist with sheet-metal design options — or redesigns — to enhance product features, while reducing manufacturing costs.