Streamline your medical and dental technology with precision sheet metal fabrication

QUAL-FAB works with leading medical and dental device manufacturers to produce high quality components, scale their manufacturing capacity, and simplify their supply chain. We are ISO 9001 certified, and we invest in the latest manufacturing technology and state-of-the-art equipment for our 30,000 square foot facility. Some of the top medical and dental companies in the country depend on our sheet metal fabrication capabilities such as laser cutting, punching, precision brake forming, welding, high-tech CNC machining processes, and mechanical assembly.

Commercial Manufacturing Capabilities

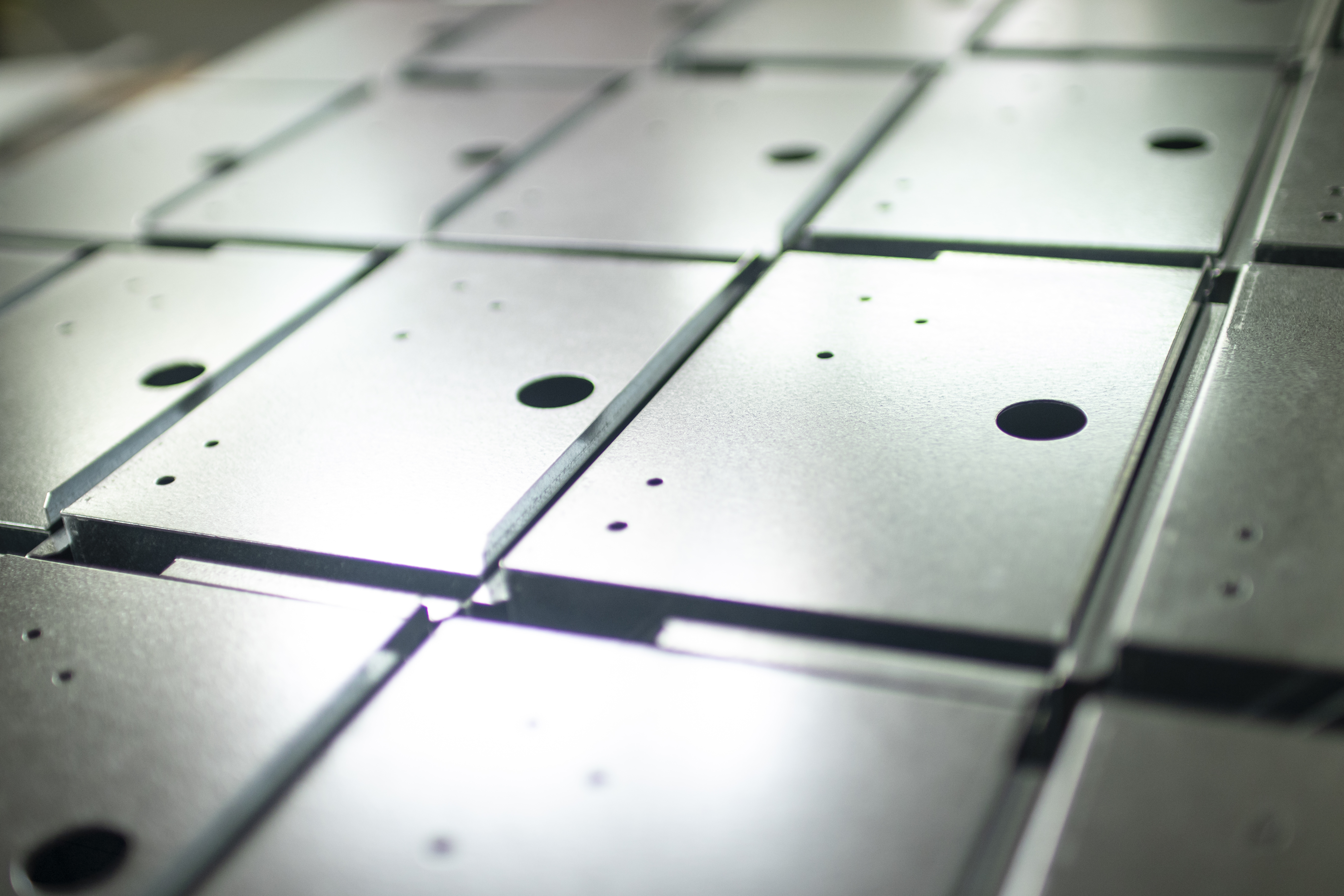

Sheet Metal Fabrication

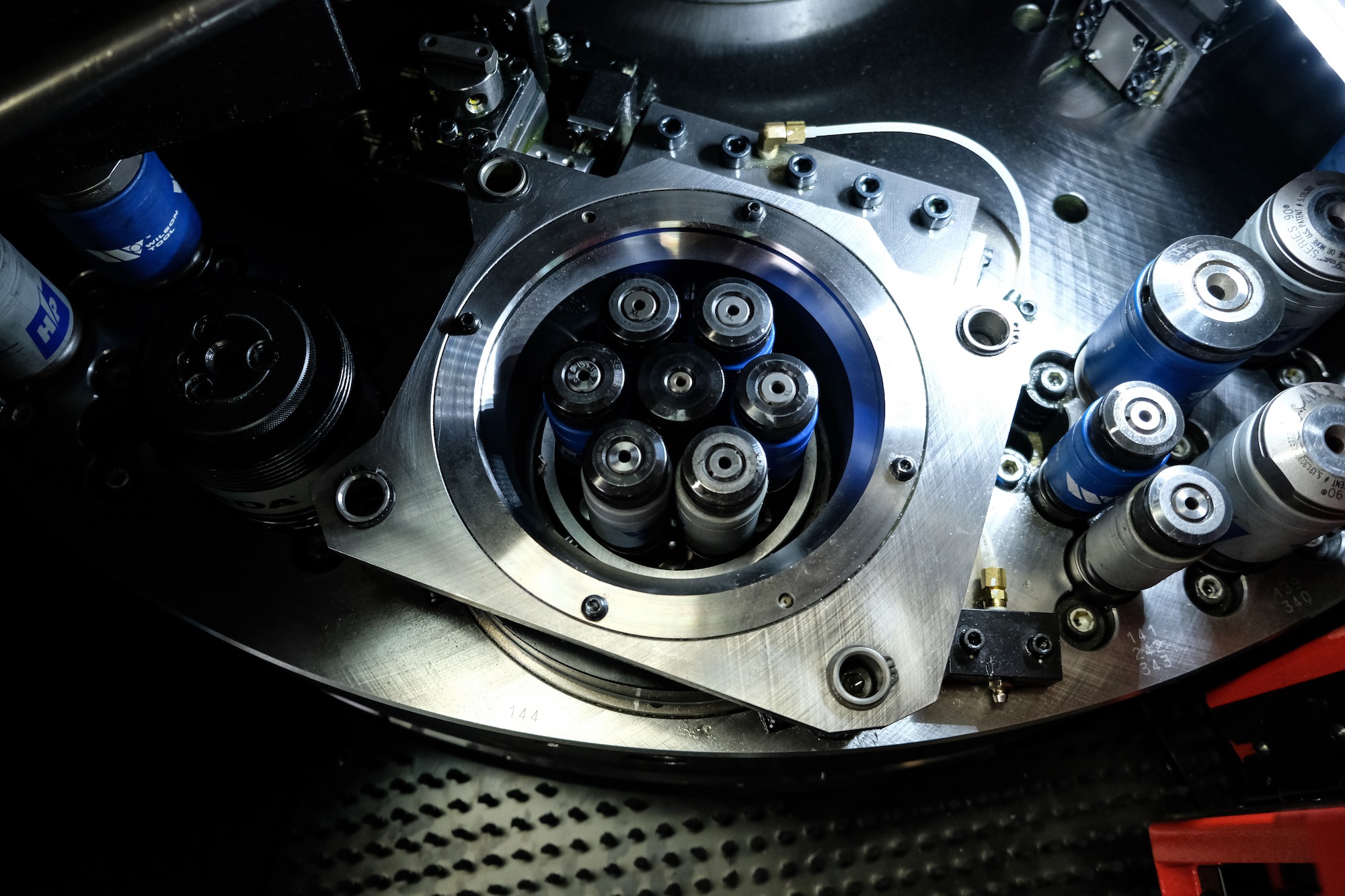

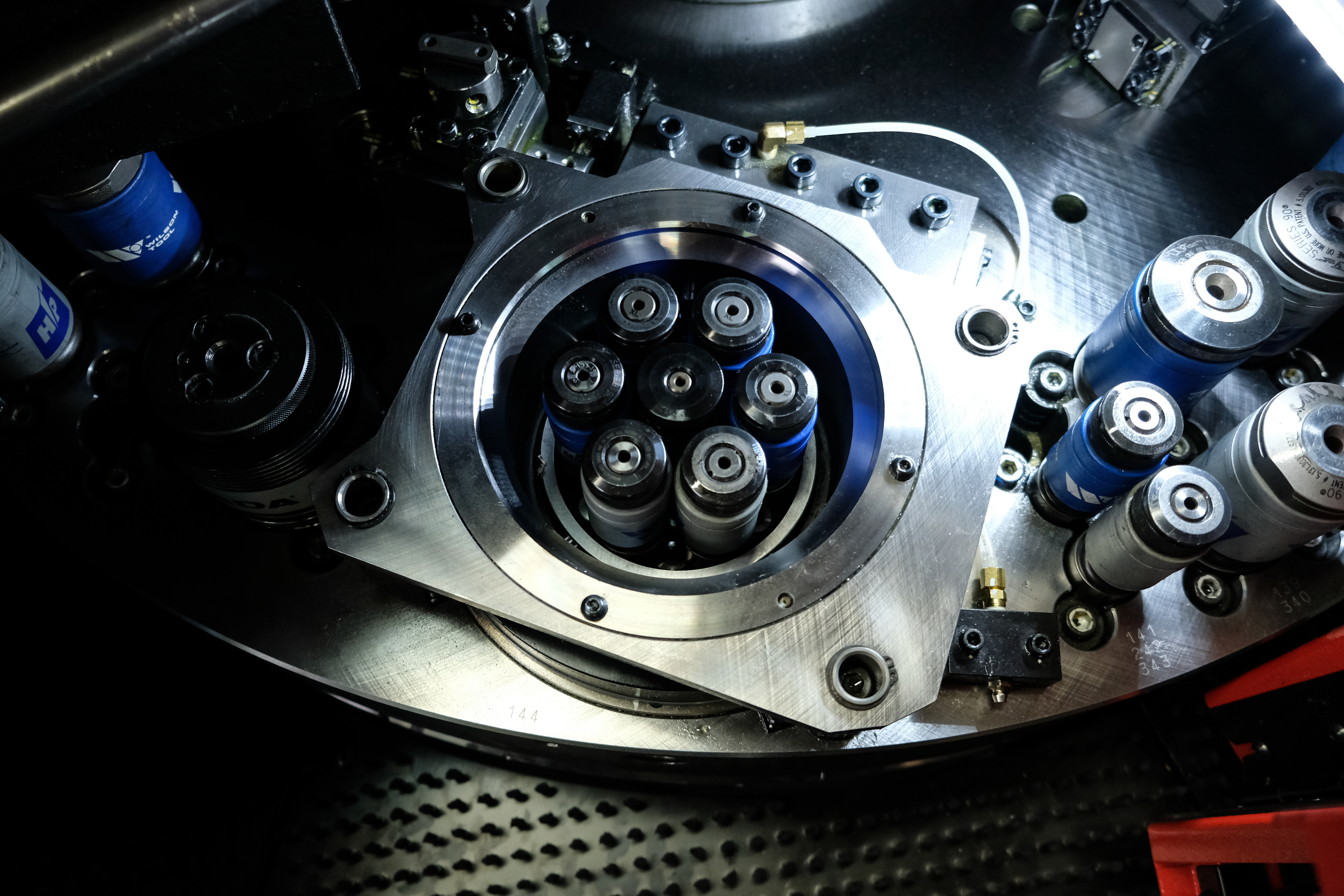

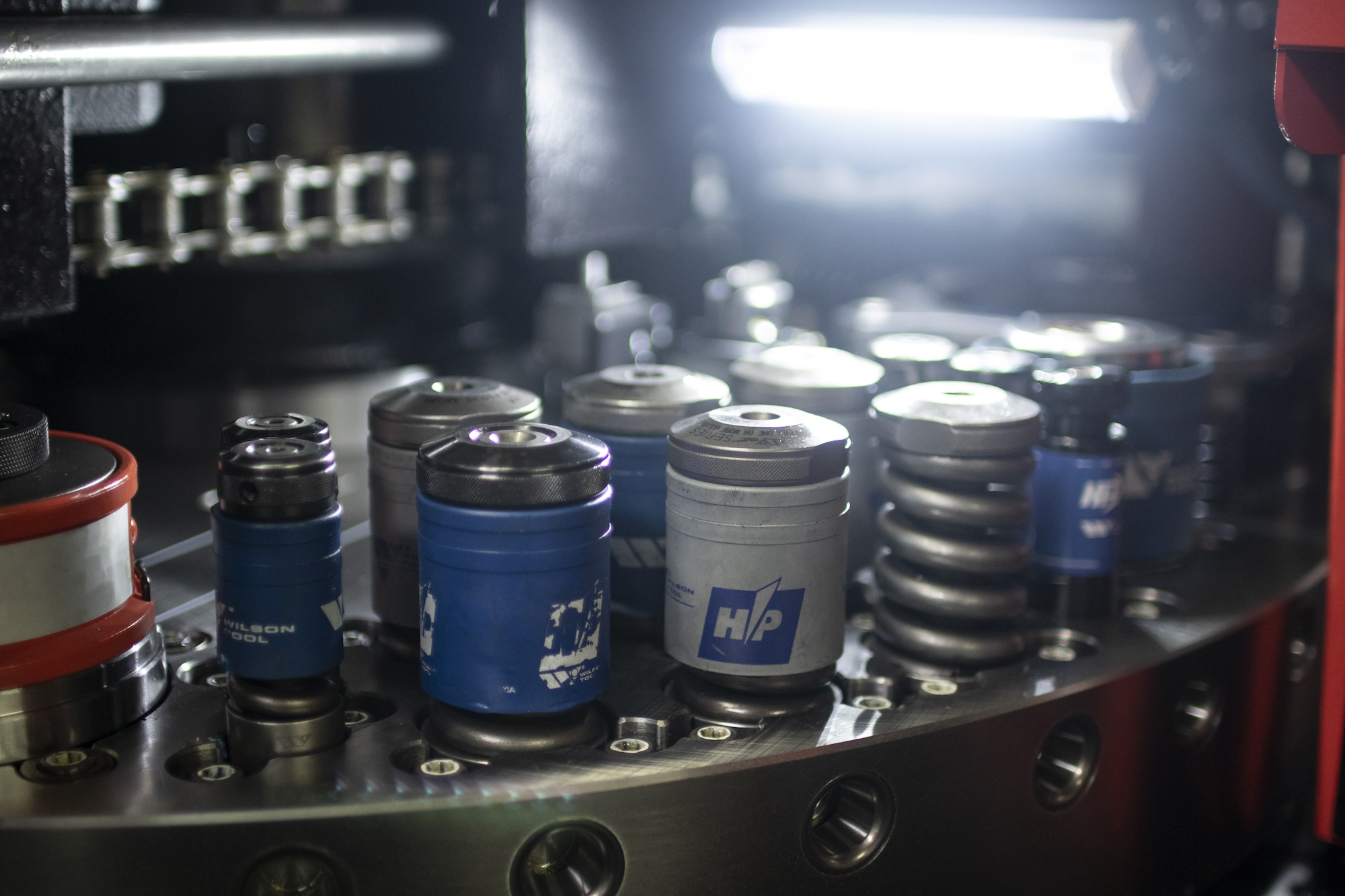

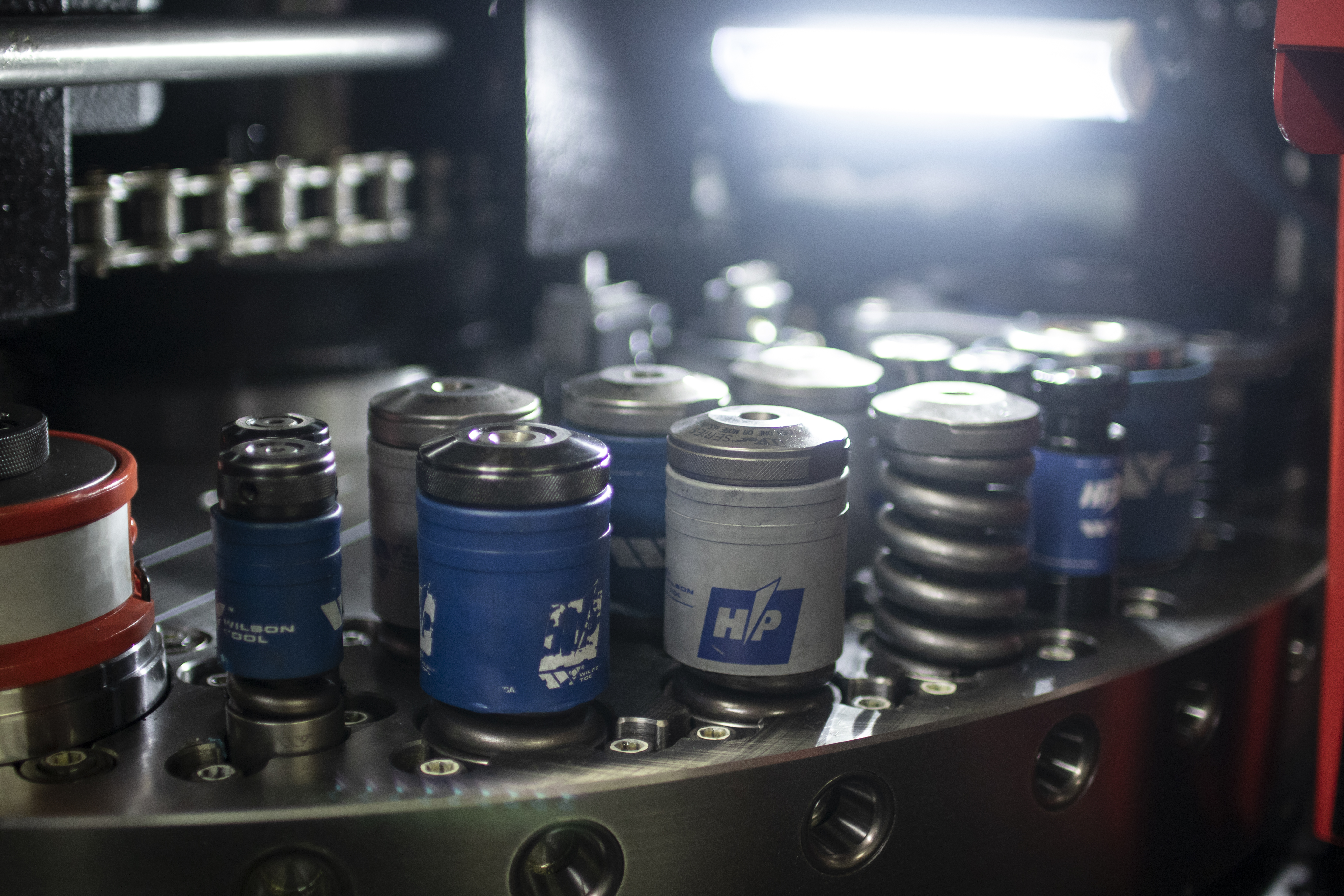

Punching

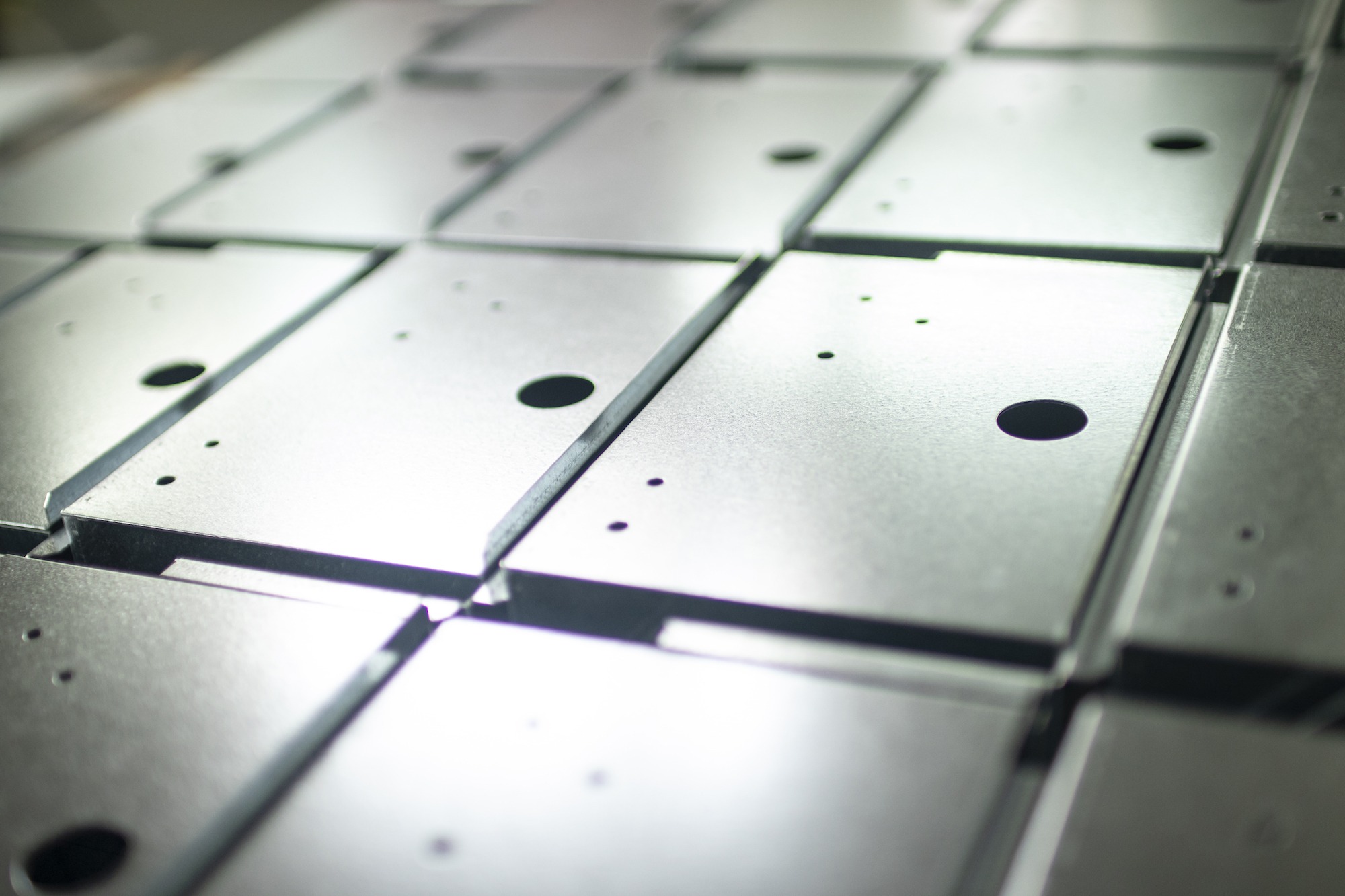

Laser Cutting

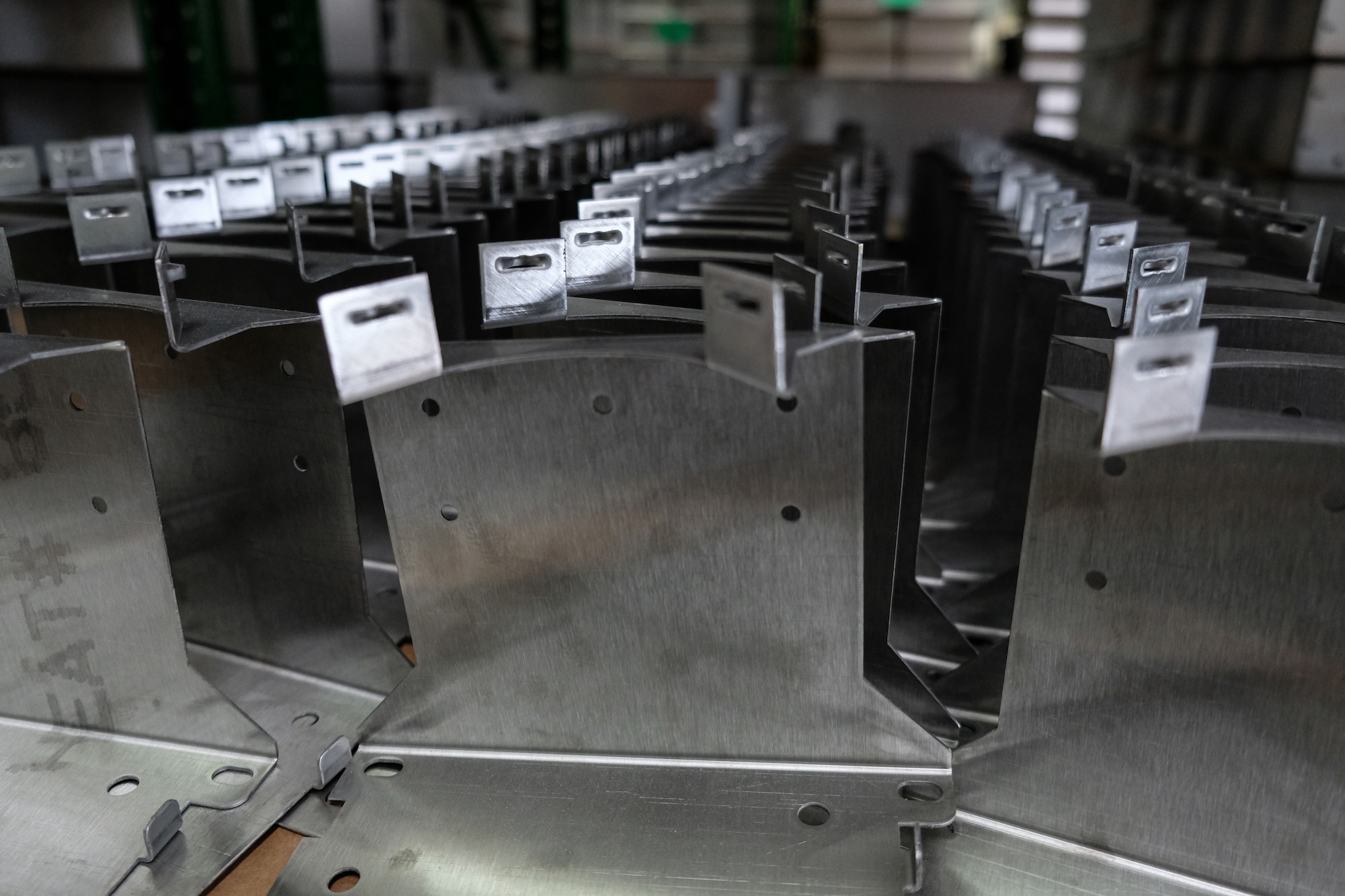

Precision Brake Forming

Hardware Insertion & Fastening

Welding

Mechanical Assembly

Managed Inventory Programs

Engineering & Design Assistance

Enterprise & Material Resource Planning

Commercial Post-Processing Capabilities

Precision machining and turnings

Heat treat

Powder coating

E-coat

Wetpaint

Chemical conversion coatings

Anodizing

Zinc plating

Tin plating

Nickel plating

Hot dip galvanize

Passivate

Silkscreen

Custom packaging

Mechanical and chemical testing/analysis

Top Medical and Dental Applications

High-volume custom manufacturing

Custom tooling brackets for medical manufacturing

Low-volume prototyping

Custom fixturing

Trusted by medical and dental engineers throughout the United States

Medical device manufacturers

Dental equipment manufacturers

Massive Production Capacity

Strategically located in Seattle, Washington, we offer custom sheet metal fabrication in our 30,000 square foot facility.

Cutting Edge Technology

We invest in the latest manufacturing technology and state-of-the-art equipment to provide our customers with an extensive range of sheet-metal fabrication capabilities.

Quality Guaranteed

QUAL-FAB is ISO 9001 certified and delivers superior quality products customized to your exact specifications — on time — as promised.